a round table discussion on training today’s workforce for tomorrow’s challenges

By necessity it seems that to be successful, today’s construction professional has to be a hands-on, multi-tasking, go-getter whose curiosity to improve performance is only surpassed by a commitment to doing things the right way. Educating a workforce across a diverse multitude of roles, both in the field and in the office, is an ever-changing challenge as new systems, new software, and new technologies continually come into play. In a round table conversation, Colorado Construction and Design sat down with a group of industry leaders to take the pulse of progress and shed some light on the future of Education Today’s Construction Professional.

Meet the Panel

Michael Gifford, President

Associated General Contractors of Colorado

As President of AGC Colorado, Michael Gifford is at the helm of Colorado’s leading professional association for the commercial construction industry. With 640 members composed of general contractors, specialty contractors, suppliers, and industry partners, Gifford has broad exposure to the pressures and opportunities that drive change in Colorado. Advocacy in public policy, economic- and workforce- development, and member participation and networking are all fundamental to the AGC’s mission.

“What gets me up in the morning is trying to move Colorado’s construction industry forward. Positive change takes time and commitment.”

Dave Davia, Executive Vice President, and CEO

Colorado Association of Mechanical and Plumbing Contractors

Proud to be a fifth-generation Colorado native, Dave Davia is the CEO of the Colorado Association of Mechanical and Plumbing Contractors (CAMPC). As the Colorado leadership of four distinct national trade organizations, CAMPC represents the interests of more than 200 members in the state legislature. Davia is particularly passionate about helping the industry prepare today’s workforce for tomorrow’s challenges. CAMPC hosts an average of 90 training days a year focused on career advancement and continues to build strategic partnerships with educators at every level.

“CAMPC doesn’t teach people how to do their job, we teach people how to advance in their careers.”

Carl Goodiel, Corporate VDC Manager

Hensel Phelps

Over more than 20 years in design and construction services, Carl Goodiel has been intimately involved in leading several firms through the transition from two-dimensional plans to the virtual construction realities being rendered in illuminating detail and depth today. As the Corporate Virtual Design and Construction Manager for Hensel Phelps, Goodiel sees a tremendous array of work being built across the country and around the globe. While technology is at the center of his services, people remain at the center of his work and corporate systems and process are only as effective as they are practical and applicable.

“A focus on technology has allowed me to operate in a lot of different realms within design and construction. A technology-trained workforce is essential to meeting tomorrow’s construction challenges.”

Ian Roth, Director of Specialized Services

From his beginnings as a licensed architect to leadership roles in Building Information Management and workflow development for both designers and builders, Ian Roth has made a career at the intersection of technology and people. MG.aec is an Autodesk premier partner offering clients a 360-degree perspective on software integration across multiple platforms. As the Director of Specialized Services for MG.aec, Roth combines a robust understanding of design and construction management software with client workflow analysis to recommend integrated solutions that foster employee growth and productivity. With offices and training centers located in 12 states, MG.aec is connected to the design and construction industry across the U.S.

“MG.aec provides me with an opportunity to see what many different clients are doing with technology and training,” says Roth. “We observe the best practices of many to help our clients better leverage the technology they already have and fill in gaps where needed.”

What is the first thing that comes to mind on Educating Today’s Construction Professional?

“Educating today’s construction professional for me is about sharing practices across a large company, developing roles, and training both internally and externally,” says Carl Goodiel of Hensel Phelps. Employing a global workforce and efficiently organizing their efforts around structured roles requires a company-wide commitment to structured processes. Goodiel points to the four pillars of the Hensel Phelps Way – people, process, partnership, and technology – as essential to success. He believes that training the construction workforce of today is fundamentally about managing change. “We have to have consistency from job to job. We can’t constantly change technology or the way we do things. We have to make a commitment to processes and systems that work and look for ways to increase workflow efficiency within that system.”

Ian Roth, a construction technology specialist at MG.aec, agrees. He adds that documenting processes, seeing ways to improve and effectively incorporating lessons learned into training are the things that come to mind. Dave Davia, CEO of CAMPC works with 160 member firms from four national trade organizations (Mechanical Service Contractors of America, Plumbing Contractors Association of America, Mechanical Contractors Association of America, and National Certified Pipe Welding Bureau) and has broad experience with the hands that do the work.

“When we look at the impacts of the recession on construction in Colorado’s construction, we know a lot of middle-tier professionals left the industry and haven’t come back,” says Dave Davia, CEO of CAMPC. As knowledge, leadership, and hands-on know-how were forced to find new careers during the recession which began in late 2008, a slight, then unnoticed gap began to form in the workforce. Compounding matters, demographics across Colorado’s construction industry suggest that senior leadership will be retiring in the next ten years and the gap will continue to grow. To ready the industry, CAMPC has partnered with other trade associations to create the Specialty Contractors Institute (SCI). “This is modularized training, for contractors by contractors. We offer four different tracks designed to enhance the transfer of knowledge from the more experienced to the less experienced.”

What are the concerns in workforce development for you?

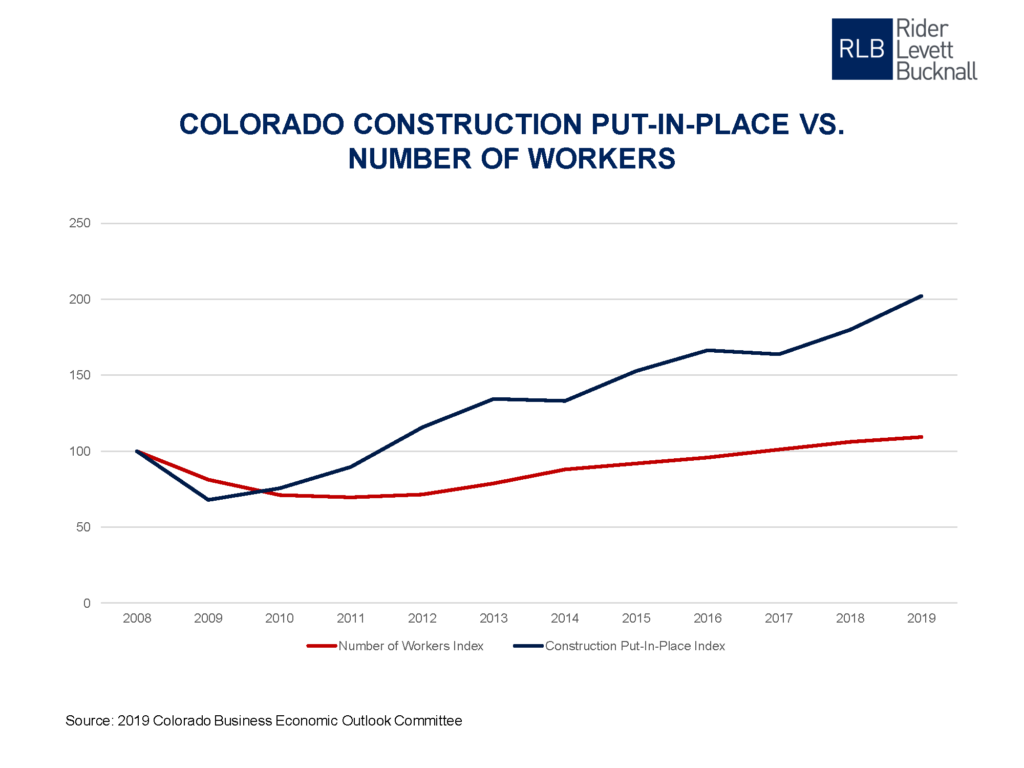

“I want to talk about productivity,” says Michael Gifford of AGC Colorado. “Somehow, in Colorado, we are doing a higher volume of construction with a flat number of employees.” With his finger on the pulse of the industry through AGC Colorado’s 640 member firms and their employees, Gifford applauds the improved performance of the workforce but struggles to sufficiently explain the stagnation in employment.

Indeed, in November 2018 the construction industry in Colorado employed 170,900 people according to the U.S. Department of Labor. This figure is relatively unchanged in the last five years though everyone in Colorado’s Construction industry acknowledges the long-standing labor shortage. Surveyed AGC Colorado members feel they are continually expected to do more work with the same workforce. Year after year, the lack of labor is reflected in project delays and higher costs.

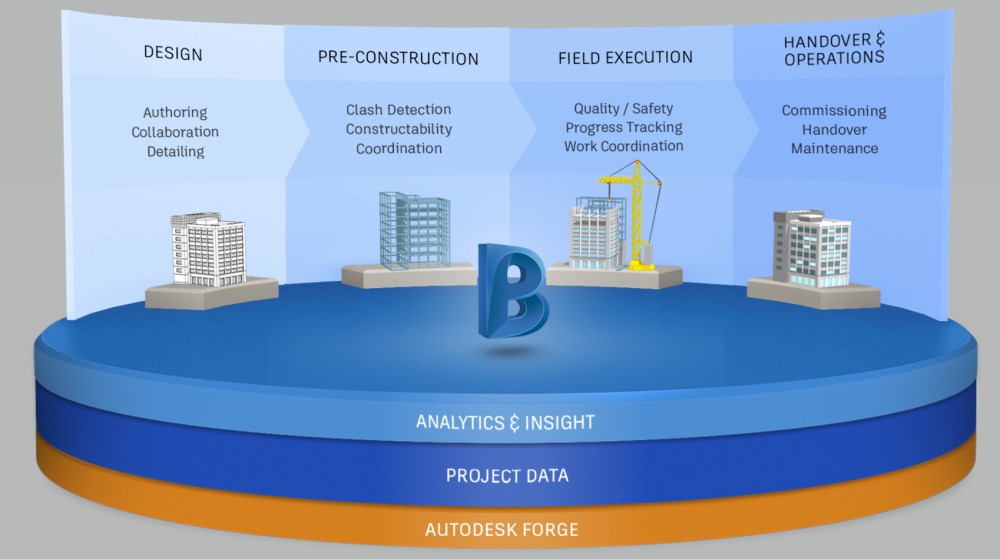

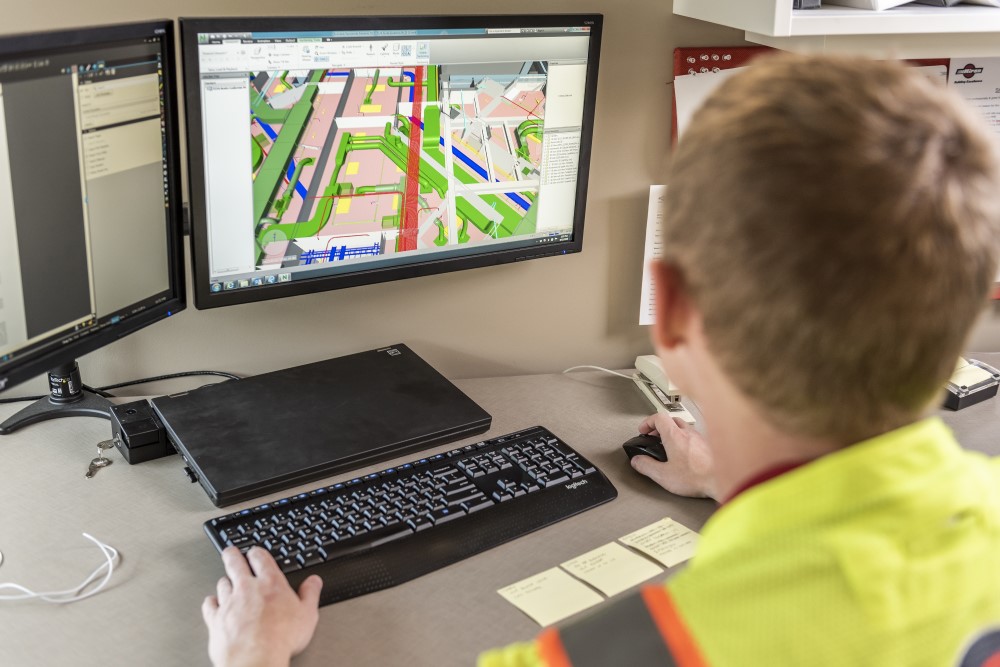

“We’re doing more with less these days,” says Goodiel of his experience at Hensel Phelps. As an internal exercise, Goodiel took the time to compare two projects of similar size and scope. The first taken from the old school drafting days and the second engaging a modern BIM workflow. “The first job employed 17 design and production staff. The second was done by five and was delivered six months faster with more effective coordination in a more collaborative environment, fewer field changes, reduced risk, and improved quality.”

As a software solutions provider, training today’s workforce to use tomorrow’s technology is an important part of what MG.aec offers. Ian Roth’s role in the firm puts him in contact with the front lines of educating today’s professional and he shares that challenges are not limited to construction.

“In training and professional development, drastically reduced attention spans and the ability to stay on track and focused is causing a shift in training structures,” says Roth. Where 20 years ago, on the job training could entail three days of class time, today’s training must be broken down into compact segments. From modularized training courses to bites as small as 30-second videos to be reviewed immediately prior to tackling a task, shortening the learning curve and increasing retention remain central to educating today’s construction professional.

Where are we today on addressing these challenges?

“The Specialty Contractor Institute’s program is designed around smaller blocks of time and applicable learning,” says Davia. Along career-oriented training tracks – Project Management, Professional Service, Field Leaders, and Leadership – the SCI’s training program is segmented into three levels based on experience. The tools acquired in each module are designed to be immediately applicable to the participants’ daily responsibilities and reinforced through practice. “We archive each training session so there is a resource to review and also a training record that follows the person through their career.”

AGC Colorado continues to see an increased demand for professional leadership training from members and now offers several different single-day training and a two-day leadership academy. All 15 of the AGC Colorado’s committees have been reworked to include leadership-level professionals and committees are intended to act as training grounds for how to take ideas from initiative to fruition.

“At Hensel Phelps, training for each role has annual goals that must be met,” says Goodiel. “This includes specific classes, field training, and importantly, training the individual who replaces you to do the job just as well as you.”

Passing knowledge from one generation to the next isn’t a new idea but documenting workflows and establishing segmented training that corresponds sequentially to the work being done is an effective strategy for improving retention.

“I don’t think one size fits all in training, nor should it,” says Roth, whose firm routinely trains both design and construction professionals across the country on technology implementation and workflow management. Roth sees great value in creating just-in-time training modules tailored to the activities at hand and encourages clients to leverage today’s technology to the fullest. “Knowledge transfer through mentorship is huge. We have the capacity to capture that transfer in many ways and share it with new hires, people in other locations, and next generations.”

Prefabrication programs are also fertile ground for on-the-job training. The repetitive motion, assembly line process of fabricating specific building components in a controlled environment allows builders to implement watch, do, teach learning strategies. Free from the demands of a job site schedule where ancillary trades are impacted by a specialty contractor’s production, prefabrication workflows make an ideal situation for bite-size, one-on-one, hands-on training right down to the nuts and bolts when needed.

What is on the horizon?

“For the 175,000 construction professionals in Colorado what is on the horizon is more and better training,” says Gifford. “Like the current prevailing wage language in contracting, in two years the U.S. Department of Labor will have similar language around mandatory, in-person training requirements as a percentage of labor. This will be a big change for the entire industry.”

“Construction’s future is so bright,” says Davia. “Sadly, construction was once considered a fallback plan, if you couldn’t make it to college. Nothing could be further from the truth. This is a dynamic, intricate, workforce collaborating through leading-edge technology to build increasingly complex, globally connected architecture in Colorado and around the world.”

“The opportunities for educating and re-educating yourself on the job, are massive in construction,” says Goodiel. “From safety to development, VDC and BIM, LEAN construction workflows, the most successful people in our industry take advantage of a tremendous opportunity to learn new skills, apply it to their work, and then mentor others as part of their career approach.”

“Training programs need to be intentional, organized, and captured,” sys Roth. “It takes a little preplanning, but today construction professionals are leveraging technology and training to great effect in their careers and lives.”

“The industry is moving. We are integrating technology, prefabrication, and training into professional responsibilities and that makes construction more attractive as a career for the next generation or any generation,” says Gifford. “Everyone here is very proud of today’s construction professional and we are all excited to keep training them for tomorrow’s challenges.”

Sean O’Keefe is an who crafts stories and content based on 20 years of experience and a keen interest in the people who make projects happen. You can reach him at sean@sokpr.com | 303.668.0717

Sean O’Keefe is an who crafts stories and content based on 20 years of experience and a keen interest in the people who make projects happen. You can reach him at sean@sokpr.com | 303.668.0717

thought leadership from the front lines of smart building technology, implementation, and long-term performance

Smart technologies of every sort continue to seep deeper into our lives, putting information, services, comfort, and convenience at our fingertips where ever we are. In today’s smart buildings seemingly, anything and everything can be automated. From individualized thermal comfort to supplemental lighting that responds to ambient daylight and increasingly untethered global connectivity the limits of technology are all being integrated to the point of becoming conventional. In a Round Table conversation, Colorado Construction & Design was delighted to discuss the amazing present and super bright future of Smart Buildings with a group of dedicated professionals committed to smartly engineering, efficiently building, and acutely commissioning technology-infused facilities in Colorado and across the country.

Our Panel

Renée Azerbegi, Ambient Energy

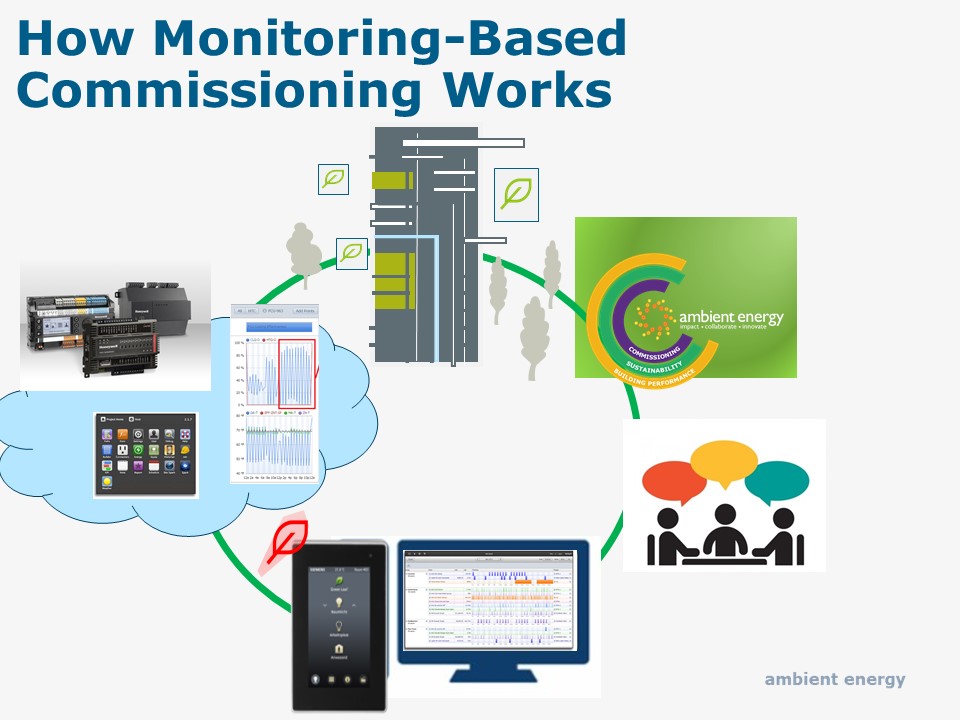

President and founder of Ambient Energy, Renée Azerbegi loves making a positive impact in the commercial building industry and on the environment through personal determination and her firm’s collective depth of experience. Ambient Energy offers a suite of services focused on building and system analysis to optimize new construction projects for operational efficiency and longevity; evaluate and improve the performance of existing buildings; or commission either as a third-party engineer. Utilizing fault-detection diagnostics and monitoring-based commissioning, Ambient Energy strives to ensure buildings operate as efficiently as possible through the whole of their lifecycle.

Bret Roberts, P.E., Control Solutions Inc.

Co-founder of Control Solutions Inc. Bret Roberts relishes the thrill of making things work, planning and seeing a complex building together from start to finish is both his business and his gratifying reward. Along with partner, Ed Welch, Roberts established Control Solutions, Inc. in 2007 by merging a wealth of experience in building automation service and installation. Gary Bales became a partner in the practice in 2013. Control Solutions Inc. contends for smart system installation projects from Colorado Springs to Fort Collins and works with clients to update and retrofit existing buildings with more advanced systems as buildings age. The firm represents Honeywell Building Automation products such as Tridium/Niagara, Honeywell WEB’s, Spyder Controllers including the new CIPer product family of controllers and I/O Modules.

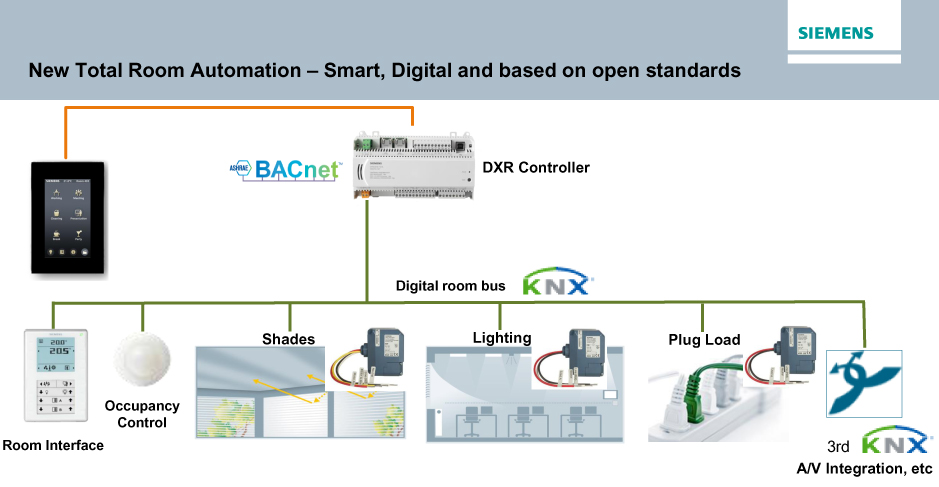

Ryan Sobeck, Siemens

A Territory Sales Manager at Siemens, Ryan Sobeck began his career in electronics working on M1 Tanks and Bradley Fighting Vehicles in the Army before getting into building automation systems implementation, design, and products 24 years ago. Today as a representative of Siemen’s Building Technologies, Control Products and Solutions, Ryan’s territory spans from Colorado north through Wyoming, Utah, Idaho, Oregon, Washington, and up to Alaska. Siemen’s showcases technology that integrates HVAC, lighting, shades, and plug loads from a single, ethernet-connected, terminal controller. Within the Building Technologies division of this global giant, Siemens is using integrated smart building technologies to optimize space and improve people’s lives.

Our Conversation

While integrating systems and technology to enhance the user experience is fundamental to smart building design, bells and whistles alone aren’t enough to make a building smart. What does?

“It starts in design,” says Roberts. “If the design is well thought-out, the rest of the project will follow that path, but if you start with a poor design it’s almost certain the finished building will underperform.” Roberts and his firm Control Solutions Inc. are among those responsible for installing the systems that have been selected and as such often feel the brunt of any bad decision making related to systems chosen in design. The technology of controlled systems has changed significantly, and everyone involved needs to be thinking holistically about smart systems, smart design, and smart installation.

“Having an owner who is driven, experienced, and knows what they want in terms of building performance almost always sets the stage for success,” adds Azerbegi, whose firm, Ambient Energy, can find itself in both pre- and post- construction roles depending on the project. “Smart design isn’t just technology, it’s holistic strategies like envelope modeling and commissioning to determine if the building is well-sealed. If it’s not, the best systems in the world won’t make it a smart building for long.”

Azerbergi points out the need for better documentation on the intended sequence of operations from mechanical and electrical engineers in the design stage to eliminate the possible risks of misinterpretation during installation. Ambient Energy likes to incorporate a series of controls integration meetings both in design and during construction to ensure efficient systems are being implemented and everyone involved is speaking the same language. Roberts is excited to share that common language has arrived.

“ASHRAE’s newest guideline, issued in July 2018 establishes a set of standardized advance sequences of operation for common HVAC systems,” says Roberts with a copy of the new standards proudly at the ready. The American Society of Heating, Refrigerating and Air-Conditioning Engineers or ASHRAE, has been devoted to the advancement of indoor-environment-control technology since it was formed in 1959. ASHRAE Guideline 36-2018 provides uniform sequences of operation for HVAC systems that are intended to maximize energy efficiency and performance, provide control stability, and allow for real-time fault detection and diagnostics. “I’ve been wanting something like this for a long time,” continues Roberts. “We need more of a common language around buildings systems and this guideline establishes a starting point that will still allow for individual and situational customization.”

The advantages of high-tech digital connectivity, functionality, and comfort have been realized in office environments and homes for some time. Where are we going next?

“Individualized controls and data harvesting are starting to be integrated into smart-phone platforms,” says Sobeck of Seimens, a technological pioneer of electrification, automation, and digitization systems and products. One such system called Comfy Comfy allows users to request heating or cooling changes, via a smartphone app, directly to the building automation system. This data can then be used to tell individuals which spaces in the office best suit their needs at any given time, ideal for free-address offices on the design desks today.

The ability to gather an immense volume of data on a smart building is what allows it to be customized around the user experience. However, analyzing and appropriately reacting to that same abundance of information is central to ensuring a smart building operates effectively day-to-day. The ability to detect, identify, and individually correct faults within a smart building system is an advantage that is easily mitigated if the building’s operation team isn’t actively monitoring and fine-tuning the system. Operators have to wield the building’s technology to save effort, expense, and all three of the Round Table participants agree there is definitely a cost of doing nothing.

“Buildings will drift upwards in energy consumption by some 2- to 3- percent a year if they aren’t actively managed,” says Azerbergi, whose role in commissioning buildings has her firm on the front lines of evaluating long-term operational expectations as the building comes to life. Though commissioning is generally required by code, most owners would probably be surprised to know that typical commissioning processes actually only test a sampling of unitary equipment rather than 100%. Perhaps more importantly, commissioning of a new building does little to account for the building’s performance once commissioning is complete unless the building operator actively monitors and controls it. “Monitoring-based commissioning integrated with fault-detection diagnostics is what we recommend,” continues Azerbergi about the need stay on top of what is happening as users occupy and make spaces their own. “Continual monitoring has been shown to save 5 to 15 percent on annual energy costs, eliminating energy drift, improving performance, and increasing user comfort.”

What does the integration of all these technologies mean for designers and builders?

The answer, it seems, is the need for yet more and better integration among the industry’s diverse range of professionals to match the requirements of changing technologies.

“For the last forty years or so, controls were the responsibility of the mechanical and lighting was the responsibility of electrical engineers,” says Roberts of a dichotomy that feels needlessly siloed, occasionally detrimentally. In today’s smart buildings’ just as systems need to talk to each other and be monitored holistically and individually, the design, implementation, commissioning, and operations processes also need to be more seamlessly integrated.

“Investing an afternoon in making sure the sequence of operations meets the owner’s objectives and the designer’s intent is essential with the systems going into today’s smart properties,” says Sobeck. Azerbergi agrees, adding that a commitment to collaboration on the technology choices and expectations will greatly reduce issues found during the commissioning process. Pre-thinking challenges together focuses the whole team on developing the best possible building for the owner’s investment.

As user expectations of workspaces have grown beyond simply hot or cold and on or off, product manufacturers have continued to push toward integrated solutions. Siemen’s DXR Controller is a single-source, remote-monitored control unit for the building’s temperature, lighting, window shades and electrical loads. On the building side, more complicated systems don’t necessarily mean more complicated construction, as long as advance coordination and an appetite for new knowledge are fundamental to the builder’s goals.

“Owners have been installing two, three, and sometimes four different control systems in a single building,” continues Sobeck, adding depth to the need for better integration in all aspects of the industry. “Single-system solutions mean one product, one installation subcontractor, and a more integrated, informed understanding of systems for optimal performance.”

Control Solutions Inc. competes for systems installation opportunities and also represents Honeywell building automation products including the CIPer product family of controllers and I/O modules. As a subcontractor helping designers understand smart systems, install, program, and start them up, Roberts sees a commitment to continuing education as essential for his firm and staff

“You can’t have too much education on all of this,” says Roberts of the continued trend toward more integrated systems requiring highly specialized and multi-faceted experts. “The systems are getting so complicated that finding enough skilled people capable of putting these systems together is my biggest challenge.”

Control Solutions Inc. is proud to represent Honeywell Building Automation products including Niagara 4 software and the new CIPer product family of controllers and I/O Modules.

Roberts nudges the green ASHRAE Guideline 36-2018 on the table forward as a next step that can be taken, immediately, industry-wide to facilitate better communication and collaboration. The complexity of systems and what is required of the professionals who design, sell, program, install, commission, or operate them will continue to increase as smart buildings and smart people get smarter out on the edge of technology and convenience.

About the Author

Sean O’Keefe is an who crafts stories and content based on 20 years of experience and a keen interest in the people who make projects happen. You can reach him at sean@sokpr.com | 303.668.0717