top-to-bottom, resilience is the new normal, and now is the new forever

Resilience (n):

The process and outcome of successfully adapting to difficult or challenging life experiences, especially through flexibility and adjustment to external and internal demands.

Architecture is an opportunity, a chance to improve on the processes and performance of predecessors across a broad spectrum of potential measuring sticks. In single-family residential, comfort, functionality, and on-trend style are likely to top homebuyers’ must-haves. Repeatable processes and readily available materials are fundamental to the builder’s profitability. Speed to market, saleability, and presence of place is what the developer is after. As for the architects and engineers, they seem to mainly want whatever they design to stand the test of time.

There is, however, a new now, which means a new normal. The catchphrase for the 21st Century – the new normal – is a ubiquitous explanation for what has become the reoccurring instant when suddenly the world turns upside down. We’ve had a few. High winds, flooding, fires, earthquakes, and plagues are age-old hazards, to which we’ve added man-made utility failures, chemical and radiological accidents, and terrorism. The latest, and greatest in terms of an overall impact on human health and wellness and the built environment must be the extreme weather events ravaging the globe and leaving a wake of devastation in their path.

And so today, the chance to change is not presented in the form of bells and whistles, or those that have and those that don’t. Rather, it’s a collection of easily implemented hows and whys that should be built into every new home from here forward. There are many resiliency measures for residential and even commercial structures that add tremendous long-term value and peace of mind for generations to come at little to no additional cost. Not so much a trend or buzzword, in architecture the new normal is resiliency, and the new forever starts right now.

“To build a resilient home or building you have to get the physics right,” says Rebecca Bryant, Principal at Watershed, a climate-centric design firm operating from Fairhope, AL. “Before you get into high-end systems or technologies, fundamentally the building form must be built to withstand extreme weather conditions. Where I live and practice along the Gulf Coast of Alabama, that means wind, water, and heat. For me, resiliency starts with a highly efficient, rock-solid building envelope that is attuned to the specific site and climatic circumstances.”

Bryant founded her firm during the 2008 recession, believing that it was a good time to reassess the way things are built in her region. She shares that while many sustainability solutions have been developed in response to climates getting hotter and dryer, along the Gulf of Mexico, the challenges are a hot, humid climate that is regularly subjected to hurricane-force winds. And termites.

“We use advanced framing techniques to create strong wood-framed buildings, that are well insulated,” says Bryant. “This means that we right-size and insulate headers, stacking studs where possible, and wrapping the home in continuous insulation to reduce the potential for condensation, which decreases efficiency and can lead to rot.”

Another easily implemented technique that could future-proof homes is to de-couple the systems from the structure. In traditional wood-framed construction, the stud wall goes up, and then holes are drilled through it so electrical wiring can be woven through. Open web trusses and the use of conduits allow system wires to be strung and later replaced, if needed, without taking down walls. By running conduit from electrical panels to the roof, and providing space for future inverters and battery systems, Watershed makes every structure future solar-ready for less than the cost of a nice dinner out.

“Everything we do is designed and built to FORTIFIED Standards,” continues Bryant of the Insurance Institute for Business & Home Safety’s (IBHS) building certification program designed specifically for resiliency, rather than sustainability. Categorized among three asset types – Home, Multifamily, and Commercial – the FORTIFIED construction method is a voluntary construction standard that goes beyond code to protect against severe weather.”

“In Alabama, insurance companies are required to provide a discount on FORTIFIED structures. This can reduce wind insurance by up to 40 percent,” says Bryant. “That has the attention of homeowners here, and FORTIFIED is becoming the standard. So, while Alabama may be a little behind on sustainability, perhaps we lead the way in resiliency.”

Like her contemporary to the east, Chandra Franklin Womack, P.E., owner and principal engineer for Aran + Franklin Engineering, Inc., in Texas City, TX sees a lot of science-based value in the FORTIFIED Standards.

“As structural engineers, our role is to add strength and longevity to the structure. Aran + Franklin operates from three offices along the Gulf Coast of Texas and one in Florida, so we design custom homes and commercial buildings to withstand extremely high winds and possible flooding,” says Franklin Womack. “In Texas, the homes are generally wood framed, while in Florida concrete is often the primary material. Aran + Franklin is accustomed to working with both.”

As a structural engineer specializing in windstorm design of custom residential, Franklin Womack distills the primary concerns homes face along the Gulf Coast down to wind and water.

“In custom home design, people tend to want a lot of windows on short walls. We build in resisting elements in the form of posts and beams that transfer the load,” says Franklin Womack. In addition to designing homes, she has a significant amount of post-disaster damage assessment experience and knows well the situational defects that cause homes to come apart in extreme weather.

“Water is worse than wind, because of its ability to infiltrate and deteriorate the building envelope,” she says. “However, the roof is where we see the most failure. Once the roof comes off, the water gets in and ruins everything. A FORTIFIED roof incorporates a few enhanced building techniques that reduce vulnerabilities and strengthen the structure in important ways.”

A FORTIFIED Roof designation assures that the roof can better withstand high wind, hurricanes, hail, thunderstorms, and even tornadoes up to EF-2. Features of a FORTIFIED Roof include wind-rated roof covers, wind and rain-resistant vents, sealed roof decks, enhanced roof deck attachments, and impact-resistant roof covers in hail-prone areas. A stronger roof begins with stronger edges. To protect this vulnerable area, FORTIFIED requires specific materials and installation methods, including a wider drip edge and a fully adhered starter strip. Sealing the roof deck beneath the roof covering – shingles, metal panels, or tiles – prevents water infiltration into the home if high winds remove portions of coverings. FORTIFIED also requires ring-shank nails, installed in an enhanced pattern, to keep the roof deck attached in high winds. This simple technique, which requires zero additional effort, nearly doubles the roof’s ability to resist wind.

FORTIFIED Silver meets the roof requirements and adds layers of additional protection. Gable ends, chimneys and attached structures are susceptible to heavy damage in severe conditions. Increased bracing and anchors around these elements prevent them from detaching in high winds. Likewise, FORTIFIED Silver Standards call for stronger garage doors. Finally, FORTIFIED Gold requires an engineered continuous load path, which specifies how the roof is fixed to the walls and how the walls are anchored to the foundation.

Beyond elevating building standards, Franklin Womack sees the FORTIFIED system as a means of increasing certainty and collaboration in the design conversation for custom residential.

“One of the challenges in custom residential is sometimes there isn’t enough collaboration between architects and engineers,” she shares. “In hurricane-prone areas, the structure, the roofing system, and the ability for windows and doors to resist high-velocity impacts are what is going to hold the house together. Better collaboration will allow enhanced building techniques to be integrated seamlessly.”

Franklin Womack suggests that FORTIFIED’s easy-to-use standards checklists offer a simple how-to guide for design professionals wishing to integrate resiliency into their work. She also points out that contractors can also become FORTIFIED Certified.

“It’s very important that structures not only be designed FORTIFIED, but also built FORTIFIED, and that’s where a well-trained workforce comes into play,” says Franklin Womack. To become Certified, industry professionals from across the full spectrum of disciplines – designers, builders, insurers, and others – can benefit from the training offered by the IBHS through FORTIFIED Wise University. Participants must complete a training course and pass the Certification test with a score of 80 or better and prove that they meet the minimum qualifications for certification.

Both Franklin Womack and Bryant agree that where they live and practice, resiliency is the backbone of good design.

“A FORTIFIED home has been designed, built, and inspected by an independent third party, so it is certain to be more resilient than a non-certified home,” says Bryant in closing. “This adds tremendous value to the home in terms of insurance savings, resale value, and when those massive storms come rolling in, peace of mind.”

Bio:

Sean O’Keefe is an who crafts stories and content based on 20 years of experience and a keen interest in the people who make projects happen. You can reach him at sean@sokpr.com | 303.668.0717

from views and vegetation to spatial hierarchy and statistical fractals, biophilia is the spine of good design

Architecture is an experience. Among the best of it, context, character, and community inform place, purpose, and point of view to shape a myriad of choices made along the way. In architecture for learning, the decisions made during design influence a learner’s capacity to absorb and retain information as much as the building provides a place from which a learner obtains an education. For researchers Bill Browning and Terri Peters, Ph.D., infusing the innate human instinct to connect with the natural world into the spaces where we live, work, learn, and play is more than a matter of aesthetics; it is a mission.

“Biophilia is about accommodating the human desire and need to connect with nature in the spaces we occupy,” says Browning, who is the managing partner of Terrapin Bright Green, a sustainability design and research consultancy committed to creating a healthier world. “On the simplest level, biophilic design begins with good views of nature through windows and enlivening the spaces we occupy with plants and natural materials. However, these are just 3 of 15 different patterns of biophilic design that can enhance the built environment. There is no shortage of evidence that these things improve cognitive functions, physical health, and psychological well-being.”

Terri Peters, Ph.D., is an architect and an assistant professor in the Department of Architecture and Science at Ryerson University in Toronto, Canada, who has devoted her career to studying human conditions that are hard to measure.

“The most effective biophilic design solutions are holistic and immersive,” says Peters. “Spatial proportions, the quality of light, textures, air flows, and smells all combine to enhance space in meaningful ways.”

Through nearly 30 years of research and consulting on biophilic design strategies, Browning shares that the established science around infusing space with nature falls into three application areas.

Nature in the Space is the literal idea of adding natural influences like views, vegetation, and daylight to invigorate space by design. The second application, Natural Analogs, is the indirect experiences of nature by including natural materials, fractal patterns, and biomorphic forms in architecture that provide accessibility to nature through non-living elements. Finally, Nature of the Spaces entails spatial experiences that apply naturally occurring spatial patterns that induce a psychological sense of calm and security within a space. For example, unimpeded views through an area enhance prospect awareness, while a wall at your back and a shelter overhead provide a comforting sense of refuge within a space.

“The effects of biophilic design decisions are quantifiable. Studies in educational environments reveal that students learn better, retain more, and enjoy the overall experience of education in spaces with biophilic influences,” says Browning. “Several studies prove that daylight variability improves visual acuity and keep us in tune with our circadian clock. Being able to see nature, even through a window, has an impact on our prefrontal cortex that helps restore our attention and allows learners to increase cognitive focus and information retention.”

According to Attention Restoration Theory, the human brain’s capacity to focus on a specific stimulus is limited – too much time on task results in directed attention fatigue. Breaking away from intense concentration in a restorative natural environment for as little as 40 seconds can reset a person’s mental state from negative to positive, enabling them to resume concentration at total capacity in a relatively short period.

“In educational settings when children are allowed access to nature during the day, teachers report students return to the classroom in a calmer state of mind and are better able to get into the next task quickly,” says Browning.

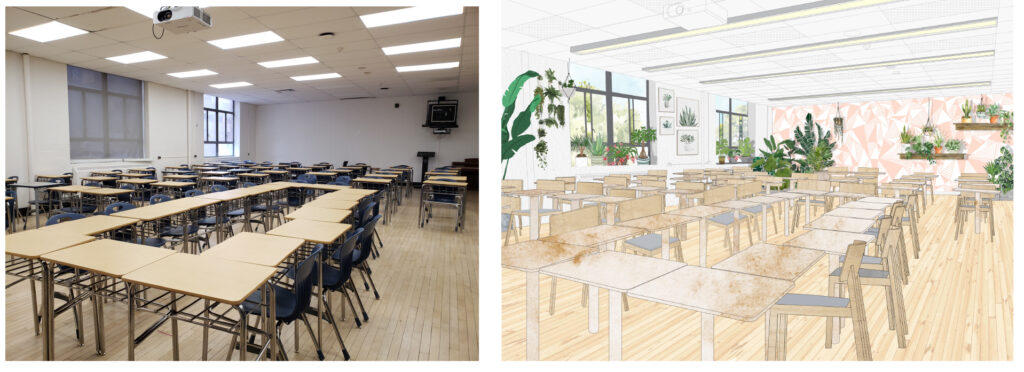

Peters shares that at Ryerson University, while participating in a classroom audit of campus facilities, the team found a lot of challenges related to classroom design, use, and spatial hierarchy.

“Issues as simple as walls cluttered with posters, mismatched chairs, and tables, and poor levels of light are examples of everyday basics that are easily improved,” says Peters. “Next semester, we will establish a test classroom that incorporates biophilic design principles and then evaluate the student and faculty experience against unchanged classrooms in the same building. In addition, we will add plants, replace lighting with a full spectrum system and clean the windows for better light and views. We will also increase spatial variability by adding hierarchy to spaces and replace wall clutter with thoughtfully selected abstract graphics of natural patterns that we believe will have measurable positive impacts.”

One of the most interesting ways biophilic design strategies enhance the experience of space is by incorporating statistical fractals. These detailed, repeating patterns are the fundamental foundation of many organic systems, existing in abundance throughout the natural world. Spiral fractals allow nature to condense itself for strength and durability against the elements; examples include pinecones, pineapples, and hurricanes. A Voronoi fractal illuminates nature’s tendency to favor efficiency and relies on linking cell structure through the shortest path between points. Examples include the skin of a giraffe, honeycombs, the cells in a leaf, and foaming bubbles.

Browning was part of a team that conducted a year-long study using simple biophilic interventions in a sixth-grade mathematics classroom in Baltimore. The changes included removing most of the visual clutter of posters from the walls, putting down carpet tiles with a wavy grass biomorphic pattern, a wallpaper frieze with an abstracted palm-leaf pattern, and automated fabric window blinds with a statistical fractal pattern based on tree branch shadows. Test scores improved dramatically, and through biometric testing, the study determined that the space helped the students with stress recovery.

“Dappled light or the experience of daylight streaming through a canopy of trees in a forest has a calming effect on human minds,” shares Browning. “We recently worked on a new guest room prototype for a hospitality client where we added LED lighting and a perforated metal panel to the ceiling plane above the entrance to the room. When the guest turns on the light, it casts a pattern of dappled light on the walls and floors that mimic the experience of stepping into a forest, which produced a calming effect.”

Browning and Peters agree that the benefits are more than improved cognitive performance when asked about the big-picture necessity for biophilic spaces in learning environments.

“In educational design, there is an ever-increasing pressure on physical spaces to offer more than mere shelter. To be competitive, Spaces need to enhance collaboration, elevate our mood, and make people feel calm and welcome,” says Peters. Unsurprisingly, Browning reveals that the corporate world leads the way on biophilic implementation in many cases.

“Corporations now realize the old model of cubical-fill workspaces don’t favor chance interactions and the sense of spontaneous combustion that compels the eureka moments that can change the trajectory of success,” says Browning. “To maximize the value of the real estate, workspaces and classrooms alike require openness, inclusivity, and the opportunity for cross-pollination among interactions.”

Browning points out that for much of his 30 plus years of experience in the field, energy efficiency has been the focus of sustainable design strategies. In the push for planet-saving sustainability, many have overlooked the fact that the cost of operating a building is only about one percent of a business’s expenses. The real value in sustainability is gained through increased human performance, personal pride of place, and the sense of satiation that comes from having access to fresh air, views of nature, and engaging interactions with others.

“In some ways, the effectiveness and simplicity of these design strategies can be intuitively obvious,” finishes Peters. “Biophilic design aims to be an immersive, multi-sensory experience of nature in space. However, there’s more to it than plants and views or bells and whistles. It’s about using color, light, texture, and nature’s ability to improve human performance. These principles can be transmitted to everything from carpet patterns to the angle of a desk to a window. In every way possible, design makes a difference.”

Bio:

Sean O’Keefe is an who crafts stories and content based on 20 years of experience and a keen interest in the people who make projects happen. You can reach him at sean@sokpr.com | 303.668.0717 .

For many, the story of a career in construction is about seeing an opportunity, taking hold and making it your own. Sadly, socially prescribed gender roles and constricted perceptions of construction as physically demanding, low-intellect work have combined with a lack of accessible entry points to largely keep women out of the industry. In this round table discussion, Colorado Construction and Design was joined by an esteemed panel of construction professionals who are eager to see change and make an impact. Covering the state of the industry; the unseen opportunities for the next generation of builders; and the difference a day can make in the lives of young women, read on. Then tell a little girl you know; she can do it.

Meet the Panel

Dana Scoggins, President

National Association of Women in Construction – Colorado Chapter

Dana Scoggins has been in construction her whole life. Born into the industry, her father was a general contractor and she was raised in the workforce. Today, she is the President of the Colorado Chapter of the National Association of Women in Construction, whose core purpose is to enhance and promote the success of women in the construction industry. She is also the Controller for Heggem-Lundquist, a painting and drywall contractor in Denver. She also co-owns a California-based Fire Sprinkler Company with her husband and has worked as an independent contractor for both Intuit & Sage, consulting on Sage 100 Contractor software. She is a certified trainer, coach, and speaker through the John Maxwell Group.

“I love the Construction Industry! This industry has afforded me opportunities that I would not have had otherwise. You have an amazing sense of accomplishment when you are a part of building something from the ground up. Women have a place in this industry and the NAWIC is here to help them find it by offering professional, educational and business opportunities, and awarding undergraduate and construction trades scholarships.”

Leela Rajasekar, Director of Construction

Douglas County School District

Leela Rajasekar earned a master’s degree in civil engineering from the University of Colorado Denver and has spent the last 20 years helping to build Colorado’s infrastructure. Her career includes an extensive tenure with the Colorado Department of Transportation where she has had her hands deep in traffic safety and identification and prevention of hazards on state highways. Currently, the Director of Construction for Douglas County School District, Leela enjoys the student reactions to facility improvements and the sense of excitement small changes can bring.”

“Construction offers a chance to improve people’s lives. Studying a traffic situation and coming up with a solution that reduces the number of accidents at an intersection is a feeling of accomplishment that never fades.”

Keller Hayes

HOYA Foundation / Transportation & Construction Girl

Keller Hayes comes to construction through life experience. She grew up on a ranch, 50 miles from anywhere, and when a road needed to be repaired the family had to figure out how to get it done. At the HOYA Foundation, Keller manages a program focused on empowering people to succeed in construction. The HOYA Foundation mentors small businesses, provides training and resources on construction issues, and sponsors a series of innovative programs focused on increasing the number of women in the transportation and construction workforce.

“The girls in our programs are exposed to an incredible range of opportunities they didn’t know existed. Transportation and Construction Girl opens their eyes to the possibilities and builds self-confidence in young women that can last a lifetime.”

Stella Hodgkins, Corporate Citizenship Manager

Stella Hodgkins’ path to construction began after she had already started toward a career in science and medicine. She returned to college in her late 20’s to earn a degree in interior design and joined an architecture practice shortly after. She then transitioned from design to sustainability consulting and eventually joined GE Johnson as an in-house sustainability specialist. Today, she is enjoying a new role with the firm, Corporate Citizenship Manager, a many-faceted position intersecting people, process, and performance.

“I love seeing a building come to life. It’s one thing to see it on paper, but quite another to see it rising out of the ground. There is a lot of problem-solving and innovation happening every day to make it come to fruition. GE Johnson is committed to being a positive force for women in the industry. We want more women to feel the incredible sense of accomplishment that comes from being a builder.”

Where does the Advancing Roles of Women in Construction conversation start?

“Advancing the role of women in construction for me starts with the fact that only 9.1 percent of American women work in the construction industry,” says Keller Hayes, of the HOYA Foundation. “There are lots of ways to bring more women into the industry, and right now more than ever the opportunity is there.”

Exposure this job sites empower young women to see a career in construction as both interesting and advantageous.

According to the Bureau of Labor Statistics, Hayes is more than right, there is an immense untapped job market for women that seems ripe with opportunity. The Bureau’s 2016 general construction statistics reveal that approximately 9.3 million men worked in construction professions compared to just 939,000 women nationally. It also reports that while women in the U.S. earn on average 81.1 percent of what men make, in the construction industry that gap is nearly closed, and women earn on average 95.7 percent of what men do.

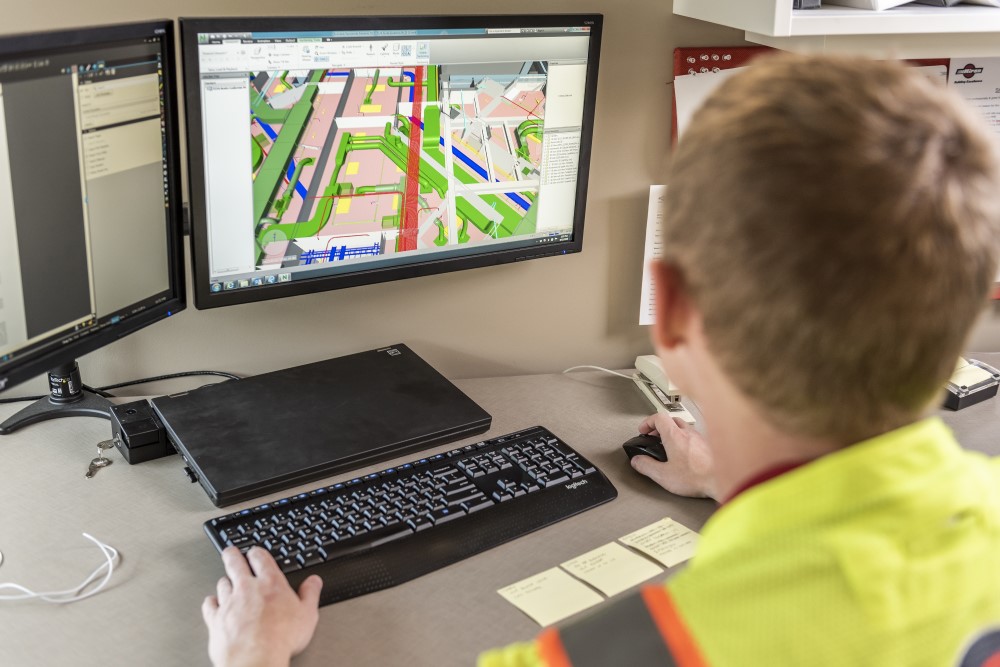

“Many people, men, and women alike including educators and guidance counselors don’t understand the wide range of roles, responsibilities, and technologies that exist in construction,” says Dana Scoggins, who has held a wide breadth of responsibilities over her 30-year career. For most non-industry people, construction looks a lot like field labor – hard hats, jeans and work boots, swinging a hammer. Those in it know there are more desk jobs than day jobs and more math than muscle. In construction, difficult challenges are rarely solved without collaboration and multi-faceted analysis and they are never almost never solved by physical strength. In 2019, general contractors of every size and specialty are engaging the leading-edge in three-dimensional building information modeling, critical path management scheduling, IT, AR/VR, and drone technology as part of their everyday lives.

“Meeting W/MBE criteria has been the industry’s primary reaction to the need for greater diversity in many regards,” says Leela Rajasekar, Director of Construction for Douglas County Schools. “Women represent half of the population, so there is a huge opportunity for growth here, but we have to provide the industry with tools to help.”

What is being done to bring more women into construction?

“Companies and individuals being proactive is what makes changes in this industry,” says Stella Hodgkins, Corporate Citizenship Manager for GE Johnson. In partnership with the Girl Scouts of Colorado, GE Johnson hosts a program called Build Like A Girl. This first-hand, day-long construction experience introduces 100 scout Cadettes and Seniors to the complexities and opportunities of big-time commercial construction. Working alongside GE Johnson employees, Scouts build little free libraries; learn about the many roles in construction and tour an active construction site. The September 2019 group got a behind the scenes look at the new U.S. Olympic Museum in Colorado Springs, seeing up close the inner workings of the building process.

One of the biggest challenges the construction industry will soon face is the wealth of knowledge leaving the industry as senior leadership retires. Many analyzing industry workforce projections predict a significant labor shortage and likely skills gap if more young workers don’t follow a career through construction. The HOYA Foundation’s Transportation and Construction Girl program strives to prove the potential of the construction industry through hands-on introductions.

“Transportation and Construction Girl is focused on opening young women’s eyes to the possibilities of construction” shares Keller Hayes. Committed to making a dent in the 9.1 percent, Transportation and Construction Girls hosts an annual lunch event and summer career days for young women between 13 and 20 who are interested in learning about the industry and its opportunities. Many of those who lend their time and expertise to the program’s success are, of course, professional women from Colorado’s booming construction industry. Having role model examples on hand is critical to eliminating common misperceptions. “We had over 600 participants at the last Transportation & Construction Girl event. One girl remarked that she’d never seen so many professional women in the same room.”

In both programs, observers routinely note how much more involved and engaged young women are when all the participants are females compared to mixed company. Shedding the idea that construction is only for boys is the first step for these young women. Recognizing that construction is still very much a male-dominated profession is the first step for the industry.

What challenges are there for women in construction?

“There are still issues to overcome, especially for women in the field,” says Scoggins, whose role as President of the Colorado Chapter of National Association of Women in Construction keeps her keenly informed. Unfortunately, as many in the industry are aware, women are still subjected to remarks, harassment, isolation, job insecurity, and even Personal Protective Equipment (PPE) is typically designed for men. There needs to be change in the workplace culture. This speaks to the importance of men in fostering the development of women in construction.

Hodgkins nods in agreement. Though somewhat new to her role as Corporate Citizenship Manager, she is invigorated by the responsibility and realities in equal measure.

“Leadership in any workplace initiative has to be modeled from the top down,” says Hodgkins. “Corporate diversity programs may be authentic, but the attitudes and actions of the firm’s leaders are what makes the difference in the way other employees behave. Incorporating behaviors that empower women is an important first step.”

“Public entities, heads of companies, leaders of industry all need to step up and support advancing women’s roles in construction and many other fields,” says Rajasekar, whose perspective is informed by more than 30 years in the public sector at CDOT and now Douglas County. “We also need men to raise awareness, look for ways to increase inclusivity. Don’t ask women to be note-takers, instead show that you value their input in key decisions.” “Seeing women in leadership roles makes a big impact. We enjoy career days with the RTD, whose leadership is 38 percent women,” finishes Hayes of one of the Transportation and Construction Girl programs long-time supporter. Indeed, 9 of the RTD’s 15-member board are women. “When the General Manager of RTD comes down to talk to these young women and says if you’re ready to work, we want you in this industry, that has a big impact.”

About the Author

Sean O’Keefe is an who crafts stories and content based on 20 years of experience and a keen interest in the people who make projects happen. You can reach him at sean@sokpr.com | 303.668.0717

a round table discussion on training today’s workforce for tomorrow’s challenges

By necessity it seems that to be successful, today’s construction professional has to be a hands-on, multi-tasking, go-getter whose curiosity to improve performance is only surpassed by a commitment to doing things the right way. Educating a workforce across a diverse multitude of roles, both in the field and in the office, is an ever-changing challenge as new systems, new software, and new technologies continually come into play. In a round table conversation, Colorado Construction and Design sat down with a group of industry leaders to take the pulse of progress and shed some light on the future of Education Today’s Construction Professional.

Meet the Panel

Michael Gifford, President

Associated General Contractors of Colorado

As President of AGC Colorado, Michael Gifford is at the helm of Colorado’s leading professional association for the commercial construction industry. With 640 members composed of general contractors, specialty contractors, suppliers, and industry partners, Gifford has broad exposure to the pressures and opportunities that drive change in Colorado. Advocacy in public policy, economic- and workforce- development, and member participation and networking are all fundamental to the AGC’s mission.

“What gets me up in the morning is trying to move Colorado’s construction industry forward. Positive change takes time and commitment.”

Dave Davia, Executive Vice President, and CEO

Colorado Association of Mechanical and Plumbing Contractors

Proud to be a fifth-generation Colorado native, Dave Davia is the CEO of the Colorado Association of Mechanical and Plumbing Contractors (CAMPC). As the Colorado leadership of four distinct national trade organizations, CAMPC represents the interests of more than 200 members in the state legislature. Davia is particularly passionate about helping the industry prepare today’s workforce for tomorrow’s challenges. CAMPC hosts an average of 90 training days a year focused on career advancement and continues to build strategic partnerships with educators at every level.

“CAMPC doesn’t teach people how to do their job, we teach people how to advance in their careers.”

Carl Goodiel, Corporate VDC Manager

Hensel Phelps

Over more than 20 years in design and construction services, Carl Goodiel has been intimately involved in leading several firms through the transition from two-dimensional plans to the virtual construction realities being rendered in illuminating detail and depth today. As the Corporate Virtual Design and Construction Manager for Hensel Phelps, Goodiel sees a tremendous array of work being built across the country and around the globe. While technology is at the center of his services, people remain at the center of his work and corporate systems and process are only as effective as they are practical and applicable.

“A focus on technology has allowed me to operate in a lot of different realms within design and construction. A technology-trained workforce is essential to meeting tomorrow’s construction challenges.”

Ian Roth, Director of Specialized Services

From his beginnings as a licensed architect to leadership roles in Building Information Management and workflow development for both designers and builders, Ian Roth has made a career at the intersection of technology and people. MG.aec is an Autodesk premier partner offering clients a 360-degree perspective on software integration across multiple platforms. As the Director of Specialized Services for MG.aec, Roth combines a robust understanding of design and construction management software with client workflow analysis to recommend integrated solutions that foster employee growth and productivity. With offices and training centers located in 12 states, MG.aec is connected to the design and construction industry across the U.S.

“MG.aec provides me with an opportunity to see what many different clients are doing with technology and training,” says Roth. “We observe the best practices of many to help our clients better leverage the technology they already have and fill in gaps where needed.”

What is the first thing that comes to mind on Educating Today’s Construction Professional?

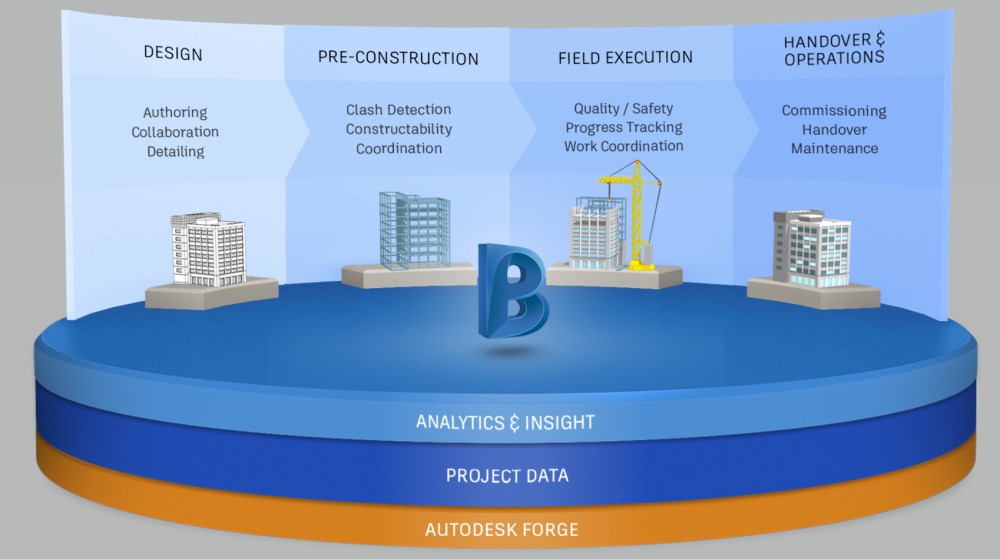

“Educating today’s construction professional for me is about sharing practices across a large company, developing roles, and training both internally and externally,” says Carl Goodiel of Hensel Phelps. Employing a global workforce and efficiently organizing their efforts around structured roles requires a company-wide commitment to structured processes. Goodiel points to the four pillars of the Hensel Phelps Way – people, process, partnership, and technology – as essential to success. He believes that training the construction workforce of today is fundamentally about managing change. “We have to have consistency from job to job. We can’t constantly change technology or the way we do things. We have to make a commitment to processes and systems that work and look for ways to increase workflow efficiency within that system.”

Ian Roth, a construction technology specialist at MG.aec, agrees. He adds that documenting processes, seeing ways to improve and effectively incorporating lessons learned into training are the things that come to mind. Dave Davia, CEO of CAMPC works with 160 member firms from four national trade organizations (Mechanical Service Contractors of America, Plumbing Contractors Association of America, Mechanical Contractors Association of America, and National Certified Pipe Welding Bureau) and has broad experience with the hands that do the work.

“When we look at the impacts of the recession on construction in Colorado’s construction, we know a lot of middle-tier professionals left the industry and haven’t come back,” says Dave Davia, CEO of CAMPC. As knowledge, leadership, and hands-on know-how were forced to find new careers during the recession which began in late 2008, a slight, then unnoticed gap began to form in the workforce. Compounding matters, demographics across Colorado’s construction industry suggest that senior leadership will be retiring in the next ten years and the gap will continue to grow. To ready the industry, CAMPC has partnered with other trade associations to create the Specialty Contractors Institute (SCI). “This is modularized training, for contractors by contractors. We offer four different tracks designed to enhance the transfer of knowledge from the more experienced to the less experienced.”

What are the concerns in workforce development for you?

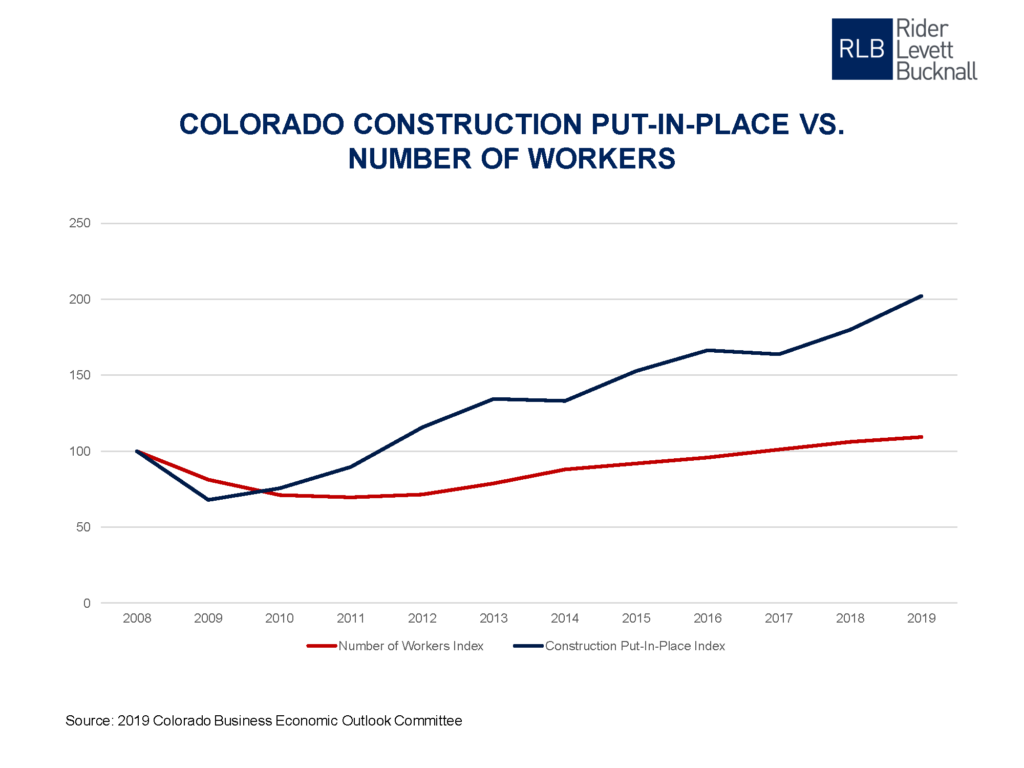

“I want to talk about productivity,” says Michael Gifford of AGC Colorado. “Somehow, in Colorado, we are doing a higher volume of construction with a flat number of employees.” With his finger on the pulse of the industry through AGC Colorado’s 640 member firms and their employees, Gifford applauds the improved performance of the workforce but struggles to sufficiently explain the stagnation in employment.

Indeed, in November 2018 the construction industry in Colorado employed 170,900 people according to the U.S. Department of Labor. This figure is relatively unchanged in the last five years though everyone in Colorado’s Construction industry acknowledges the long-standing labor shortage. Surveyed AGC Colorado members feel they are continually expected to do more work with the same workforce. Year after year, the lack of labor is reflected in project delays and higher costs.

“We’re doing more with less these days,” says Goodiel of his experience at Hensel Phelps. As an internal exercise, Goodiel took the time to compare two projects of similar size and scope. The first taken from the old school drafting days and the second engaging a modern BIM workflow. “The first job employed 17 design and production staff. The second was done by five and was delivered six months faster with more effective coordination in a more collaborative environment, fewer field changes, reduced risk, and improved quality.”

As a software solutions provider, training today’s workforce to use tomorrow’s technology is an important part of what MG.aec offers. Ian Roth’s role in the firm puts him in contact with the front lines of educating today’s professional and he shares that challenges are not limited to construction.

“In training and professional development, drastically reduced attention spans and the ability to stay on track and focused is causing a shift in training structures,” says Roth. Where 20 years ago, on the job training could entail three days of class time, today’s training must be broken down into compact segments. From modularized training courses to bites as small as 30-second videos to be reviewed immediately prior to tackling a task, shortening the learning curve and increasing retention remain central to educating today’s construction professional.

Where are we today on addressing these challenges?

“The Specialty Contractor Institute’s program is designed around smaller blocks of time and applicable learning,” says Davia. Along career-oriented training tracks – Project Management, Professional Service, Field Leaders, and Leadership – the SCI’s training program is segmented into three levels based on experience. The tools acquired in each module are designed to be immediately applicable to the participants’ daily responsibilities and reinforced through practice. “We archive each training session so there is a resource to review and also a training record that follows the person through their career.”

AGC Colorado continues to see an increased demand for professional leadership training from members and now offers several different single-day training and a two-day leadership academy. All 15 of the AGC Colorado’s committees have been reworked to include leadership-level professionals and committees are intended to act as training grounds for how to take ideas from initiative to fruition.

“At Hensel Phelps, training for each role has annual goals that must be met,” says Goodiel. “This includes specific classes, field training, and importantly, training the individual who replaces you to do the job just as well as you.”

Passing knowledge from one generation to the next isn’t a new idea but documenting workflows and establishing segmented training that corresponds sequentially to the work being done is an effective strategy for improving retention.

“I don’t think one size fits all in training, nor should it,” says Roth, whose firm routinely trains both design and construction professionals across the country on technology implementation and workflow management. Roth sees great value in creating just-in-time training modules tailored to the activities at hand and encourages clients to leverage today’s technology to the fullest. “Knowledge transfer through mentorship is huge. We have the capacity to capture that transfer in many ways and share it with new hires, people in other locations, and next generations.”

Prefabrication programs are also fertile ground for on-the-job training. The repetitive motion, assembly line process of fabricating specific building components in a controlled environment allows builders to implement watch, do, teach learning strategies. Free from the demands of a job site schedule where ancillary trades are impacted by a specialty contractor’s production, prefabrication workflows make an ideal situation for bite-size, one-on-one, hands-on training right down to the nuts and bolts when needed.

What is on the horizon?

“For the 175,000 construction professionals in Colorado what is on the horizon is more and better training,” says Gifford. “Like the current prevailing wage language in contracting, in two years the U.S. Department of Labor will have similar language around mandatory, in-person training requirements as a percentage of labor. This will be a big change for the entire industry.”

“Construction’s future is so bright,” says Davia. “Sadly, construction was once considered a fallback plan, if you couldn’t make it to college. Nothing could be further from the truth. This is a dynamic, intricate, workforce collaborating through leading-edge technology to build increasingly complex, globally connected architecture in Colorado and around the world.”

“The opportunities for educating and re-educating yourself on the job, are massive in construction,” says Goodiel. “From safety to development, VDC and BIM, LEAN construction workflows, the most successful people in our industry take advantage of a tremendous opportunity to learn new skills, apply it to their work, and then mentor others as part of their career approach.”

“Training programs need to be intentional, organized, and captured,” sys Roth. “It takes a little preplanning, but today construction professionals are leveraging technology and training to great effect in their careers and lives.”

“The industry is moving. We are integrating technology, prefabrication, and training into professional responsibilities and that makes construction more attractive as a career for the next generation or any generation,” says Gifford. “Everyone here is very proud of today’s construction professional and we are all excited to keep training them for tomorrow’s challenges.”

Sean O’Keefe is an who crafts stories and content based on 20 years of experience and a keen interest in the people who make projects happen. You can reach him at sean@sokpr.com | 303.668.0717

Sean O’Keefe is an who crafts stories and content based on 20 years of experience and a keen interest in the people who make projects happen. You can reach him at sean@sokpr.com | 303.668.0717

thought leadership from the front lines of smart building technology, implementation, and long-term performance

Smart technologies of every sort continue to seep deeper into our lives, putting information, services, comfort, and convenience at our fingertips where ever we are. In today’s smart buildings seemingly, anything and everything can be automated. From individualized thermal comfort to supplemental lighting that responds to ambient daylight and increasingly untethered global connectivity the limits of technology are all being integrated to the point of becoming conventional. In a Round Table conversation, Colorado Construction & Design was delighted to discuss the amazing present and super bright future of Smart Buildings with a group of dedicated professionals committed to smartly engineering, efficiently building, and acutely commissioning technology-infused facilities in Colorado and across the country.

Our Panel

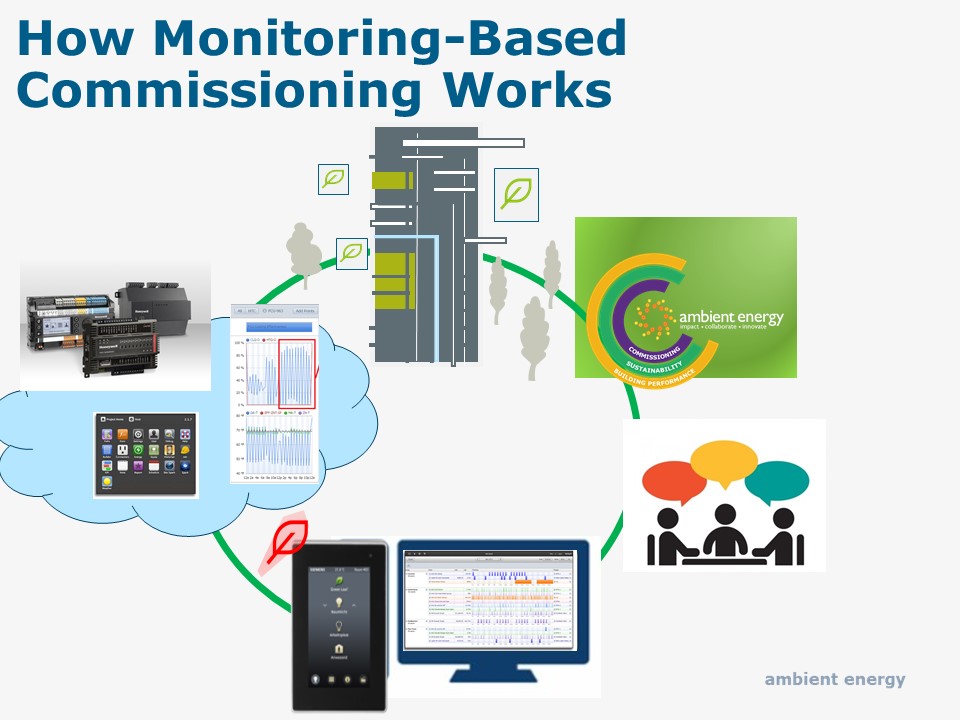

Renée Azerbegi, Ambient Energy

President and founder of Ambient Energy, Renée Azerbegi loves making a positive impact in the commercial building industry and on the environment through personal determination and her firm’s collective depth of experience. Ambient Energy offers a suite of services focused on building and system analysis to optimize new construction projects for operational efficiency and longevity; evaluate and improve the performance of existing buildings; or commission either as a third-party engineer. Utilizing fault-detection diagnostics and monitoring-based commissioning, Ambient Energy strives to ensure buildings operate as efficiently as possible through the whole of their lifecycle.

Bret Roberts, P.E., Control Solutions Inc.

Co-founder of Control Solutions Inc. Bret Roberts relishes the thrill of making things work, planning and seeing a complex building together from start to finish is both his business and his gratifying reward. Along with partner, Ed Welch, Roberts established Control Solutions, Inc. in 2007 by merging a wealth of experience in building automation service and installation. Gary Bales became a partner in the practice in 2013. Control Solutions Inc. contends for smart system installation projects from Colorado Springs to Fort Collins and works with clients to update and retrofit existing buildings with more advanced systems as buildings age. The firm represents Honeywell Building Automation products such as Tridium/Niagara, Honeywell WEB’s, Spyder Controllers including the new CIPer product family of controllers and I/O Modules.

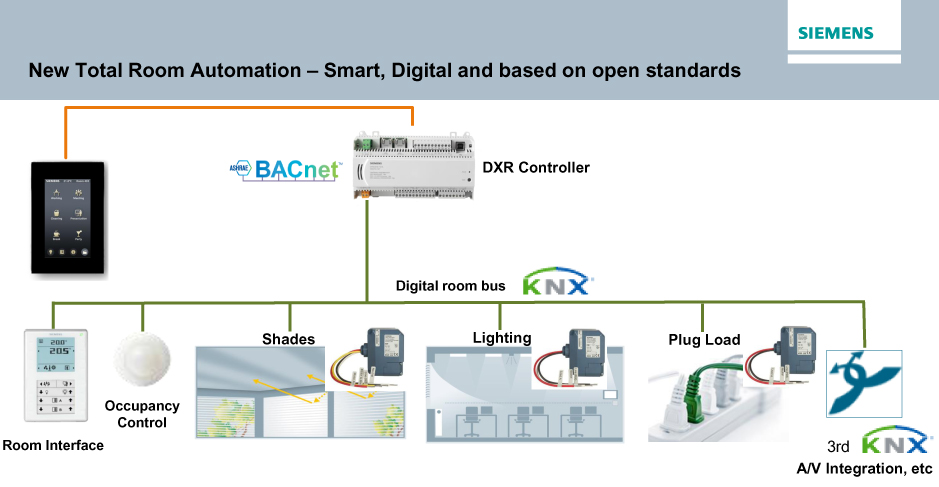

Ryan Sobeck, Siemens

A Territory Sales Manager at Siemens, Ryan Sobeck began his career in electronics working on M1 Tanks and Bradley Fighting Vehicles in the Army before getting into building automation systems implementation, design, and products 24 years ago. Today as a representative of Siemen’s Building Technologies, Control Products and Solutions, Ryan’s territory spans from Colorado north through Wyoming, Utah, Idaho, Oregon, Washington, and up to Alaska. Siemen’s showcases technology that integrates HVAC, lighting, shades, and plug loads from a single, ethernet-connected, terminal controller. Within the Building Technologies division of this global giant, Siemens is using integrated smart building technologies to optimize space and improve people’s lives.

Our Conversation

While integrating systems and technology to enhance the user experience is fundamental to smart building design, bells and whistles alone aren’t enough to make a building smart. What does?

“It starts in design,” says Roberts. “If the design is well thought-out, the rest of the project will follow that path, but if you start with a poor design it’s almost certain the finished building will underperform.” Roberts and his firm Control Solutions Inc. are among those responsible for installing the systems that have been selected and as such often feel the brunt of any bad decision making related to systems chosen in design. The technology of controlled systems has changed significantly, and everyone involved needs to be thinking holistically about smart systems, smart design, and smart installation.

“Having an owner who is driven, experienced, and knows what they want in terms of building performance almost always sets the stage for success,” adds Azerbegi, whose firm, Ambient Energy, can find itself in both pre- and post- construction roles depending on the project. “Smart design isn’t just technology, it’s holistic strategies like envelope modeling and commissioning to determine if the building is well-sealed. If it’s not, the best systems in the world won’t make it a smart building for long.”

Azerbergi points out the need for better documentation on the intended sequence of operations from mechanical and electrical engineers in the design stage to eliminate the possible risks of misinterpretation during installation. Ambient Energy likes to incorporate a series of controls integration meetings both in design and during construction to ensure efficient systems are being implemented and everyone involved is speaking the same language. Roberts is excited to share that common language has arrived.

“ASHRAE’s newest guideline, issued in July 2018 establishes a set of standardized advance sequences of operation for common HVAC systems,” says Roberts with a copy of the new standards proudly at the ready. The American Society of Heating, Refrigerating and Air-Conditioning Engineers or ASHRAE, has been devoted to the advancement of indoor-environment-control technology since it was formed in 1959. ASHRAE Guideline 36-2018 provides uniform sequences of operation for HVAC systems that are intended to maximize energy efficiency and performance, provide control stability, and allow for real-time fault detection and diagnostics. “I’ve been wanting something like this for a long time,” continues Roberts. “We need more of a common language around buildings systems and this guideline establishes a starting point that will still allow for individual and situational customization.”

The advantages of high-tech digital connectivity, functionality, and comfort have been realized in office environments and homes for some time. Where are we going next?

“Individualized controls and data harvesting are starting to be integrated into smart-phone platforms,” says Sobeck of Seimens, a technological pioneer of electrification, automation, and digitization systems and products. One such system called Comfy Comfy allows users to request heating or cooling changes, via a smartphone app, directly to the building automation system. This data can then be used to tell individuals which spaces in the office best suit their needs at any given time, ideal for free-address offices on the design desks today.

The ability to gather an immense volume of data on a smart building is what allows it to be customized around the user experience. However, analyzing and appropriately reacting to that same abundance of information is central to ensuring a smart building operates effectively day-to-day. The ability to detect, identify, and individually correct faults within a smart building system is an advantage that is easily mitigated if the building’s operation team isn’t actively monitoring and fine-tuning the system. Operators have to wield the building’s technology to save effort, expense, and all three of the Round Table participants agree there is definitely a cost of doing nothing.

“Buildings will drift upwards in energy consumption by some 2- to 3- percent a year if they aren’t actively managed,” says Azerbergi, whose role in commissioning buildings has her firm on the front lines of evaluating long-term operational expectations as the building comes to life. Though commissioning is generally required by code, most owners would probably be surprised to know that typical commissioning processes actually only test a sampling of unitary equipment rather than 100%. Perhaps more importantly, commissioning of a new building does little to account for the building’s performance once commissioning is complete unless the building operator actively monitors and controls it. “Monitoring-based commissioning integrated with fault-detection diagnostics is what we recommend,” continues Azerbergi about the need stay on top of what is happening as users occupy and make spaces their own. “Continual monitoring has been shown to save 5 to 15 percent on annual energy costs, eliminating energy drift, improving performance, and increasing user comfort.”

What does the integration of all these technologies mean for designers and builders?

The answer, it seems, is the need for yet more and better integration among the industry’s diverse range of professionals to match the requirements of changing technologies.

“For the last forty years or so, controls were the responsibility of the mechanical and lighting was the responsibility of electrical engineers,” says Roberts of a dichotomy that feels needlessly siloed, occasionally detrimentally. In today’s smart buildings’ just as systems need to talk to each other and be monitored holistically and individually, the design, implementation, commissioning, and operations processes also need to be more seamlessly integrated.

“Investing an afternoon in making sure the sequence of operations meets the owner’s objectives and the designer’s intent is essential with the systems going into today’s smart properties,” says Sobeck. Azerbergi agrees, adding that a commitment to collaboration on the technology choices and expectations will greatly reduce issues found during the commissioning process. Pre-thinking challenges together focuses the whole team on developing the best possible building for the owner’s investment.

As user expectations of workspaces have grown beyond simply hot or cold and on or off, product manufacturers have continued to push toward integrated solutions. Siemen’s DXR Controller is a single-source, remote-monitored control unit for the building’s temperature, lighting, window shades and electrical loads. On the building side, more complicated systems don’t necessarily mean more complicated construction, as long as advance coordination and an appetite for new knowledge are fundamental to the builder’s goals.

“Owners have been installing two, three, and sometimes four different control systems in a single building,” continues Sobeck, adding depth to the need for better integration in all aspects of the industry. “Single-system solutions mean one product, one installation subcontractor, and a more integrated, informed understanding of systems for optimal performance.”

Control Solutions Inc. competes for systems installation opportunities and also represents Honeywell building automation products including the CIPer product family of controllers and I/O modules. As a subcontractor helping designers understand smart systems, install, program, and start them up, Roberts sees a commitment to continuing education as essential for his firm and staff

“You can’t have too much education on all of this,” says Roberts of the continued trend toward more integrated systems requiring highly specialized and multi-faceted experts. “The systems are getting so complicated that finding enough skilled people capable of putting these systems together is my biggest challenge.”

Control Solutions Inc. is proud to represent Honeywell Building Automation products including Niagara 4 software and the new CIPer product family of controllers and I/O Modules.

Roberts nudges the green ASHRAE Guideline 36-2018 on the table forward as a next step that can be taken, immediately, industry-wide to facilitate better communication and collaboration. The complexity of systems and what is required of the professionals who design, sell, program, install, commission, or operate them will continue to increase as smart buildings and smart people get smarter out on the edge of technology and convenience.

About the Author

Sean O’Keefe is an who crafts stories and content based on 20 years of experience and a keen interest in the people who make projects happen. You can reach him at sean@sokpr.com | 303.668.0717