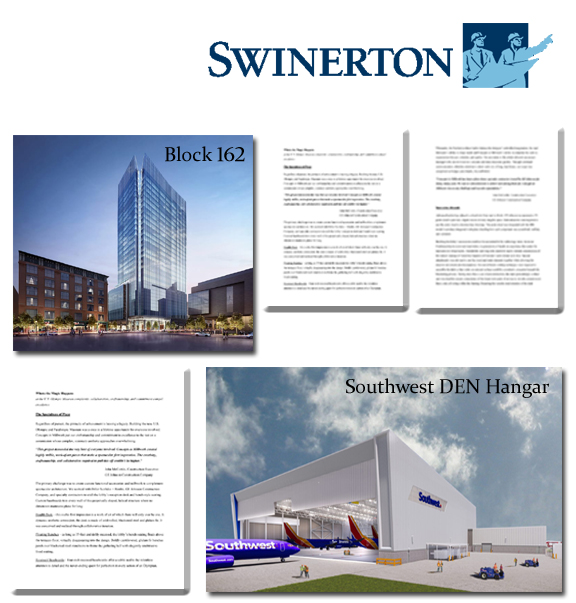

Southwest Airlines DEN Hangar

Swinerton

By Sean O’Keefe

AEC Award Writer

An Investment of Permanence

Solutions

Southwest Airlines’ DEN Hangar represents an investment of permanence in Colorado. Designed to house three 737 airplanes and park eight more on the apron, the 128,000-SF hangar is the first of its kind at DEN in 30 years: moving Colorado from flyover country to an epicenter of national aviation.

This heavy steel and structural concrete building boasts a 270-FT clear span, 48,000 cubic yards of concrete, and a reduced carbon footprint thanks to team problem-solving. Beyond the daunting size and specialized nature, distinguishing elements of this project included building a site-adapted prototype, construction on an active airfield, changing fire suppression systems, monthly-spending restrictions, and builder-invested project financing. To welcome Southwest Airlines to Colorado, Swinerton proudly fostered mutually advantageous relationships among many intersecting interests.

“DEN is a key cog for Southwest. We expect this hangar to be in operation for the next 50 years. It was designed and built for airplanes that don’t even exist today.”

Jay Fretwell Sr Manager Facilities Projects,

Southwest Airlines

Excellence

After the originally selected builder couldn’t commit to the aggressive schedule and refused responsibility for consequential damages, Swinerton replaced them. Southwest’s fun corporate culture meshed immediately with Swinerton Colorado’s laid-back vibe and can-do attitude.

Houston Review: With a similar hangar in Houston roughly 50 percent complete when preconstruction began, there was an excellent opportunity to consider means and methods, assess value engineering, and improve sequences and logistics with architects at Ghafari. Swinerton noted that exterior precast panels braced into the hangar obstructed opportunities for concurrent underground work. An alternative detail to the precast panels allowed exterior bracing, saving significant time and coordination.

Tech-Pits: Likewise, Swinerton studied the high-tech, aircraft service pits within the hangar floor. At two stations per aircraft, the six prefabricated, fiberglass units incorporate everything required to power and maintain the planes. Recessed roughly 14’ into the hangar floor, which slopes half a percent for drainage, the lip of these pits must be dead-to-nuts even when the concrete is poured.

Max Spend: Southwest’s original schedule extended 17 to 19 months from the July 2019 start. COVID changed everything. Eight months into construction, Southwest’s delivery strategy switched from speed-to-market to trickle along. Their first requirement was to restrict monthly spending to $3M. The CPM schedule and all subcontractor schedules had to be re-sequenced against this monthly burn. Cash-flow allocations had to be within five percent.

Project Financing: In re-evaluating design plans, building code and operational issues were uncovered that required Southwest to add scope to the project. However, with COVID limiting available funding, Swinerton partnered with Southwest to finance part of the added scope to keep the project moving until funding restrictions were lifted.

Innovations

Caissons: Colorado’s expansive soil required a 10’ deep cut for the entire footprint, to be structurally refilled. To save time and money, Swinerton took the excavation down to a sweet spot five or six feet below the planned excavation. Once the 300 caisson bores were drilled to 55’ feet, The pier caps and grade beams were formed before the balance of the structural fill was added to level the foundation.

Recycled Concrete: Onsite, DEN’s waste concrete storage yard was directly across a fence line. Working with Southwest and DEN, Swinerton brought in a crusher and recycled the concrete as subgrade fill. This saved tremendous time and money that would have been spent on hauling, material acquisition, and labor, while significantly reducing the building’s embodied carbon count.

Slab Pours: During preconstruction, Swinerton voiced concerns with the constructability of the concrete as designed for Houston. Southwest elected to proceed as planned and the first sections poured showed distress. Swinerton brought in a concrete consultant to precisely define pour sequences and saw cuts that adapted the design to site conditions. A hopscotch pour pattern allowed slab sections to cure before adjoining sections were poured against them, making this a job within a job.

Superstructure: Though structural steel wasn’t Design-Build, Swinerton was heavily involved in assessing and re-detailing the superstructure plan. In scrutinizing the design criteria for steel fabrication, XYZ Subcontractor realized that as designed, significant cost overruns were likely. We worked with XZY Structural Engineering to redesign connection criteria to incorporate more readily available material sizes. This correction saved an estimated $1M in overruns and the fabricator didn’t miss a single day of production.

Mega Door: The massive hangar required a massive door. Technically five doors in one, the Mega Door, is a fabric overhead door that stretches the length of the building. It folds up in sections, either individually, in groups, or all together.

Box Truss: Stretching the full 270’ of the hangar, the central overhead structural member weighs 180,000 lbs. Because the prototype was developed Design-Build, bolted connections were taken to the max, which added a lot of weight and created budget challenges. Due to FAA regulations limiting crane heights next to the taxiway, installation required an exhaustive search for the right combination of low boom height and strength. In a single day, a 500-ton Hydro crane and a 300-ton conventional crane swung the truss into place and held it there until enough bolts and welds were in place to cut it loose. Due to the extreme length and loading, Swinerton engaged a 3D laser scan of the truss on the ground, once it was in place, and after it was roof loaded to validate that the camber remained within tolerance.

Fire Suppression: Mid-way through the project, DEN announced they intended to eliminate further use of the specified fire suppression system because the foam involved contains an unwanted, forever chemical. To make the system upgrade a wash on costs, Swinerton found savings in the elimination of specialty concrete and subgrade connections. DEN hadn’t built a hangar since opening in 1995, and today’s technology is significantly different. Inspections and testing were intense. The overhead fire suppression system is required to dispense foam 3’ high, 5’ off the perimeter of the building within three minutes of being released. When tested, the foam reached the 3’ at 5’ mark in 2:47. The overhead system is one of five fire suppression systems on this project.

“Swinerton’s knowledge of the airport, the city, and Colorado’s trade workforce made this project a success. Award-winning work doesn’t happen without great teams.”

John Nimry, Senior Aviation Architect

Ghafari Associates

Safety:

Airside Coordination: The challenges of building on an active airfield are immense. Swinerton orchestrated project phasing to conduct the bulk of vertical construction without encroaching on the Airport Operations Area (AOA). For most of the project, personnel, equipment, and materials all moved in and out via landside egress while the AOA Fence remained in place. Eventually, construction had to connect the hangar and apron to the taxiway. The connection to the secure side was planned, coordinated, and approved on multiple levels. All personnel operating within the AOA were badged, as were any vehicles or equipment that crossed the perimeter.

COVID: Many layers of complexity were added when COVID-19 hit. Daily temperature checks, masks, handwashing stations, social distancing, and a continual commitment to sanitizing everything people touched on the job site were among heightened pandemic safety practices.

Basic Safety: Swinerton’s safety slogan is ‘your family needs you’ and basic safety is a daily routine. Teams start every day with a stretch and flex and safety talk tied to the day’s activities. When steel is swinging from cranes, safety talks focus on working beneath overhead activities and detailing cone pathways used to demarcate underground plumbing. The building’s roofline had four different elevations, reaching a peak at 120’ off the ground. A series of scaffolding stair towers had to be erected and connected to create a safe, consistent vertical pathway to the upper levels of construction.

Contribution

Beyond building a high-tech, commercial aircraft maintenance facility at the world’s third busiest airport, the rewards of this work are in the relationships forged along the way. Southwest set the tone for fun and despite the slow-down and restrictions caused by COVID, it has been a blast.

DEN is a huge economic driver for Colorado and the entire intermountain region. This project kept a vast workforce employed throughout the pandemic while achieving a nearly 20 percent MWBE utilization rate and demonstrates Southwest’s long-term commitment to Denver. Swinerton was honored to roll out the red carpet; diligently helping Southwest navigate Denver’s permitting and inspections processes and sourcing specialized expertise to resolve specialized circumstances in concrete, craning, and coordination. We reused rubbish to save weeks of work and a significant amount of embodied carbon. We re-sequenced our entire workload eight months into the project to accommodate spending restrictions and even financed part of the work when the chips were down.

This hangar represents an investment of permanence that will beneficially impact the citizens and the state of Colorado for generations to come.

“With COVID, there were many opportunities for this project to derail. Thanks to the incredible support, investment, and tenacity of Swinerton, we brought this in on budget – a phenomenal feat.”

Jay Fretwell Sr Manager Facilities Projects

Southwest Airlines

If you need a professional AEC Award Writer for architecture, engineering, construction, planning, or development, contact Sean today.